SOLIDWORKS 2023 optimises your product development process, enabling you to get more done in less time, with the ability to freely iterate and enhance designs, while creating high-performing, high-quality designs refined to the highest possible degree.

Invenio is an authorised SOLIDWORKS reseller in Australia and New Zealand.

SOLIDWORKS 3D CAD

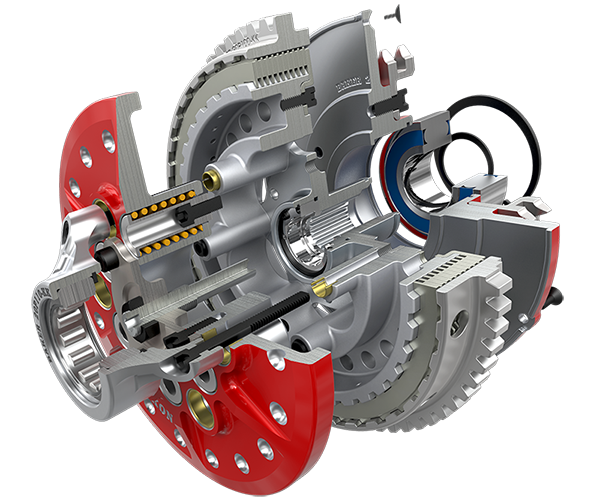

Intuitive 3D design and product development solutions from SOLIDWORKS let you conceptualize, create, validate, communicate, manage, and transform your innovative ideas into great product designs.

Dramatically improve the way you develop and manufacture products. As the foundation for the entire SOLIDWORKS suite of product development solutions, SOLIDWORKS CAD packages cover design, simulation, cost estimation, manufacturability checks, CAM, sustainable design, and data management.

By providing best-in-class, tightly integrated tools for every area of product development and management, SOLIDWORKS enables enterprises to speed each stage of the development cycle by allowing all disciplines to work concurrently, starting with concepts all the way through to manufacturing.

Benefits

- Powerful design functionality and ease of use

- Process-driven solutions keep focus on big picture

- Easy-to-deploy data management facilitates collaboration

- Virtual prototyping drives innovation, improves quality

- Integrated design-to-manufacturing gets products built faster

STANDARD

Get up to speed quickly and benefit from this powerful 3D design and manufacturing solution. Along with part, assembly, and 2D drawing functionality, specialized tools are included for sheet metal, weldments, surfacing, molds, product configuration, design analysis, DFM, and CAM. CAM included with an active subscription.

PROFESSIONAL

SOLIDWORKS Professional builds on the capabilities of SOLIDWORKS Standard with ECAD/MCAD collaboration, automated cost estimation, collaboration capabilities, design and drawing checking, a sophisticated components and parts library, and advanced photorealistic rendering.

PREMIUM

SOLIDWORKS Premium builds on SOLIDWORKS Professional by adding structural and motion analysis capabilities, advanced surface flattening, reverse engineering, and electrical cable and pipe routing functionality.

Feature Comparison

Standard

Professional

Premium

SOLIDWORKS 3D CAD

Create sophisticated part and assembly designs quickly and efficiently with SOLIDWORKS 3D design software. Powerful, easy-to-use design capabilities combined with a range of tools for drawing creation, design analysis, cost estimation, rendering, animation, and file management create an intuitive system for developing innovative products that make you more productive, lowers costs, and accelerates your time-to-market.

Part and Assembly Modeling

Handle all aspects of your part and assembly modeling with the SOLIDWORKS 3D design system for transforming ideas and concepts into virtual 3D models. For conceptual design, create 3D designs quickly using imported images, simple sketches, or scanned 3D data, and then add more details as the design evolves. Assembly structure planning lets you quickly lay out your design assembly structure and then export to SOLIDWORKS for automatically creating CAD files. Direct model editing lets you manipulate and modify 3D geometry working directly on 3D CAD models.

2D Drawings

Create production-ready 2D drawings that are always current and clearly communicate how your design should be manufactured and assembled. SOLIDWORKS associativity links a 2D drawing directly with a 3D solid model so updates to the 3D model can be automatically reflected in the 2D drawing. SOLIDWORKS accelerates your design process, saving time and development costs while increasing productivity.

Design Reuse and Automation

Leverage existing engineering data to create new designs and speed up new product development. With SOLIDWORKS, a range of tools helps you reuse existing 3D CAD models and 2D drawings, which accelerates your design process, saves time and development costs, and increases productivity. SOLIDWORKS search, automation, and configuration tools simplify the reuse of existing design data to create new designs.

Collaborate and Share CAD Data

SOLIDWORKS product collaboration tools help members of your design team work closely with other project stakeholders, outside vendors and customers. You can also protect proprietary design data before sharing it beyond your organization. and to manage project data, and control design revisions. SOLIDWORKS product collaboration tools include many innovative, time saving features such as 3D Interconnect, eDrawings®, and 3D Mark Up of parts and assemblies.

Interference Check

Before going into production, verify that your parts and assemblies will fit, assemble, and operate correctly with SOLIDWORKS Interference Check. Fully integrated with CAD, you can use Interference Check in 2D and 3D while you design to accelerate your product development process, and analyze tolerances to assess manufacturability.

First-Pass Analysis Tools

SOLIDWORKS SimulationXpress is a first-pass analysis tool that lets you perform basic stress analysis on individual parts. You can quickly determine effects of force and pressure and generate reports to document results.

CAM Programming (SOLIDWORKS CAM)

SOLIDWORKS CAM Standard powered by CAMWorks® is an integrated 2.5-axis milling and 2-axis lathe programming solution. By utilizing the emerging technologies of Model-Based Definition (MBD) and Knowledge-Based Machining (KBM), SOLIDWORKS CAM can rapidly transform your Design-to-Manufacturing process by improving communication, reducing errors, reducing cycle times, and increasing your product quality.

SOLIDWORKS CAM Standard included with active subscription of SOLIDWORKS Standard, Professional or Premium.

Design for Manufacturing (DFM)

To ensure your product can be manufactured, SOLIDWORKS provides 3D tools for reviewing your design early in the development process. It is much easier and less costly to correct issues found during the design stage than correcting them during manufacturing planning or after your design is in production.

Productivity Tools

SOLIDWORKS has a variety of tools designed to make you more productive, including capabilities for design analysis, comparison, checking, and reporting.

Advanced CAD File Import/Export and 3D Interconnect

SOLIDWORKS provides more than 30 translators to convert incoming CAD data into SOLIDWORKS 3D CAD format or to export SOLIDWORKS data to other CAD products. 3D Interconnect opens most major CAD formats directly in SOLIDWORKS with no need to convert or save the data as a SOLIDWORKS file.

CAD Libraries (SOLIDWORKS Toolbox)

SOLIDWORKS CAD libraries provide you access for easily accessing, locating, downloading, saving, and sharing prebuilt 3D CAD models and commonly reused CAD data.

Design for Cost (SOLIDWORKS Costing)

SOLIDWORKS automatic cost estimation tools are fully integrated with 3D CAD, enabling you to continuously check your designs against cost targets. Easily monitor manufacturing costs as you design, thereby avoiding costly redesigns and production delays. Manufacturers can also use SOLIDWORKS cost estimation tools to automate quoting processes.

ECAD/MCAD Collaboration (CircuitWorks)

Share data between electrical CAD (ECAD) and mechanical CAD (MCAD) designers using CircuitWorks™. CircuitWorks enables you to share, compare, update, and track electrical design data so users can quickly resolve electrical- mechanical integration and collaboration problems.

CAD Standards Checking (Design Checker)

Establish design standards and check drawings (or models) with SOLIDWORKS to create uniform designs and documentation. Use SOLIDWORKS to establish design standards, and then check drawings (or models) against them as you design to ensure consistent and complete drawing outputs.

Collaboration with eDrawings Professional

Use eDrawings® software to increase collaboration, accelerate your design process, and increase productivity by viewing SOLIDWORKS 3D models and 2D drawings in an email-ready format. eDrawings Professional allows users to quickly and accurately view, measure, and mark-up designs which improves communication between designers, manufacturers, and customers.

Automated Tolerance Stack-Up Analysis (TolAnalyst)

The TolAnalyst tolerance analysis tool automatically checks the effects of tolerances on parts and assemblies to ensure consistent fit of components and to verify tolerancing schemes before a product goes into production. The tolerance analysis can be rerun if a dimensioning or tolerancing change is made, enabling you to get to an optimized tolerancing scheme.

Advanced Photorealistic Rendering (SOLIDWORKS Visualize)

SOLIDWORKS Visualize Standard lets you create compelling visual content of your 3D designs with ease and flexibility. By utilizing photo-quality content early in the design process, useful early feedback can be received so you can make more informed design decisions.

SOLIDWORKS File Management

SOLIDWORKS PDM Standard provides CAD file management that enables individual users and small workgroups to manage project data, control design revisions, and control access to files.

Reverse Engineering (ScanTo3D)

With reverse engineering, you can recreate designs based on ones that already exist, accelerating product development, reducing risk, saving time, and increasing productivity. Use the ScanTo3D capability to import, edit, evaluate, and create solid geometry from scanned point cloud and mesh data.

Time-based Motion Analysis

Evaluate how your product will perform and move throughout its operational cycle with motion analysis using SOLIDWORKS Simulation. Visualize your product moving as it would in the real world, measure the forces and loads on your design, and use the data to correctly size motors and create the best mechanism for ensuring product performance, quality, and safety.

Linear Static Analysis for Parts and Assemblies

Linear stress analysis using SOLIDWORKS Simulation can be a regular part of your design process, reducing the need for costly prototypes, eliminating rework and delays, and saving time and development costs. Linear stress analysis calculates the stresses and deformations of geometry. SOLIDWORKS Simulation uses Finite Element Analysis (FEA) methods to discretise design components into solid, shell, or beam elements and uses linear stress analysis to determine the response of parts and assemblies.

Pipe and Tube Routing

Use the wide range of tools in SOLIDWORKS Premium to simplify the design and documentation of piping and tubing for a wide range of systems and applications, including machinery, skid systems, and process plant piping.

Electrical Cable and Wiring Harness Routing

SOLIDWORKS Premium includes design tools that build a path of pipes, tubes, or electrical cables for assemblies. Routing creates a special type of subassembly that builds a path of pipes, tubes, or electrical cables between components.

Advanced Surface Flattening

Many products are manufactured by forming a flat material, such as sheet metal stock, into complex shapes. SOLIDWORKS advanced surface flattening functionality provides control and flexibility for flattening these complex surfaces.

Rectangular and Other Section Routing

SOLIDWORKS Routing can be used to route rectangular and round sections that include ducting, cable trays, conveyors, material handling chutes, and other systems.