CAMWorks is an intuitive, feature-based and associative CAM software that helps you increase productivity and maximise CNC machining efficiency

Benefits

Program Smarter and Machine Faster. With feature based machining, the proprietary Tech DB feature and the ability to save and reuse your best programming practices, you can reduce programming time by 80% and machining time by 85%.

Accelerate new product development by as much as 80%. Because CAMWorks is both feature-based and associative with the design model, changes made to the design model are made easily and the toolpaths in CAMWorks can update automatically.

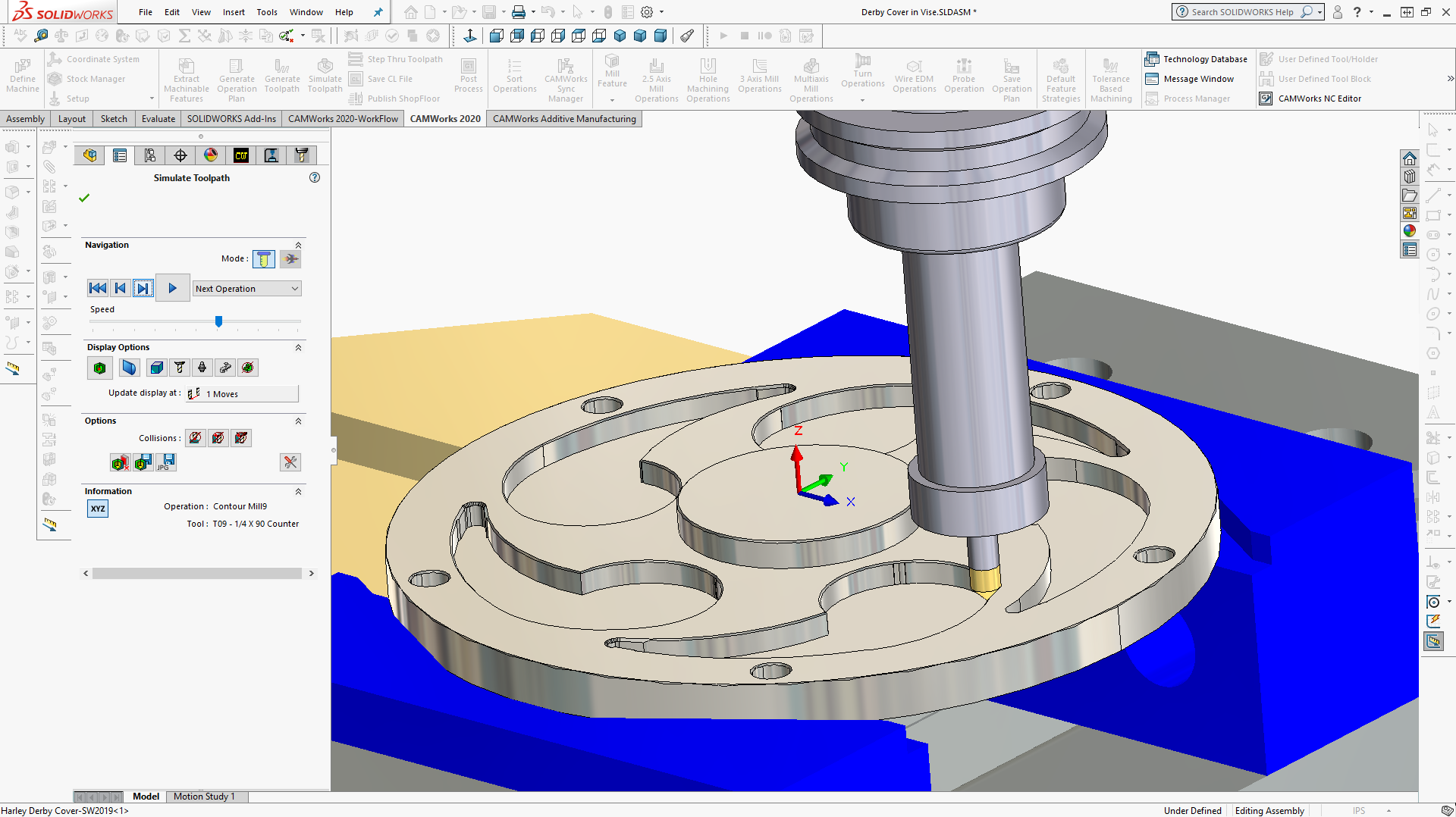

Easy to use with a single common user interface for all of your CAD and CAM needs. CAMWorks full integration inside SolidWorks brings with it the ease of use of a single user interface for all of your CAD/CAM needs, including solid modeling, complex milling and turning, multi-tasking machining, and wire and sinker EDM technology.

CAMWorks integrates all of the engineering and manufacturing information required to produce the part into a single common database. CAMWorks full integration inside SolidWorks allows all of the data for both engineering and manufacturing to be stored in a single common database. This is facilitated since the CAM data is stored within the CAD (SolidWorks) file itself.

CAMWorks 2021

CAMWorks 2021 is the most advanced CAM software available and fully integrated with SOLIDWORKS. Contact us to learn what’s new in CAMWorks 2021 and to view our Top Features in CAMWorks 2021 webinar!

2.5 Axis Milling

CAMWorks’ standard 2.5 axis module comes with 4th and 5th axis pre-positioning capability and assembly mode machining. Includes automatic roughing, finishing, thread milling, face milling and single-point cycles.

3 Axis Milling

The 3 axis milling module is built on the basis of Feature Based Machining, Knowledge Based Machining, Complete Toolpath Associativity to Solid Models and CAMWorks Volumill for toolpath generation. Machine complex, contoured surfaces used in mold making and aerospace applications

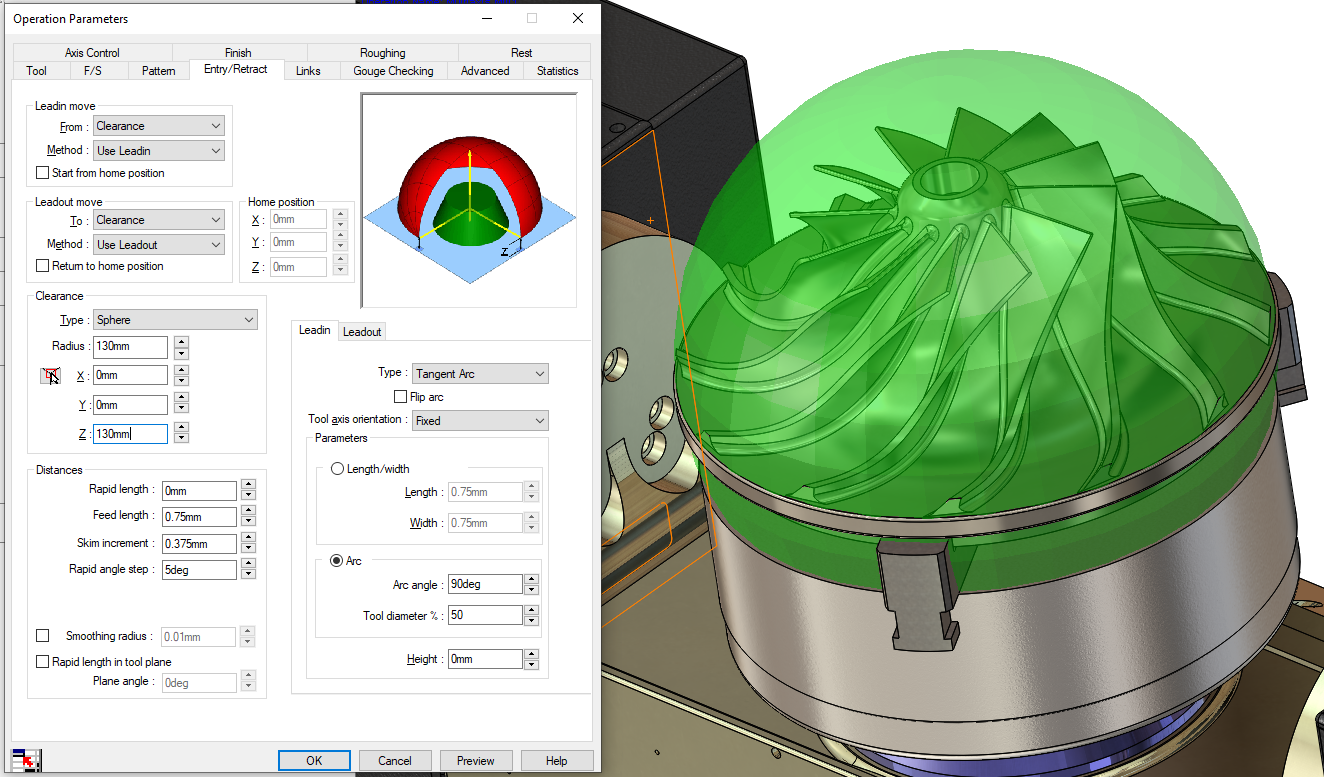

Multi-Axis Milling

Including 2.5 axis and 3 axis milling, the multi-axis module unlocks greater quality and productivity from 4/5 axis machines. The simultaneous machining programming software allows the creation of toolpaths across complex shapes that could not be machined on 3 Axis machines.

Mill-Turn

A solution for both milling and turning on the same machine tool, enabling greater productivity and flexibility. Supports C, Y and B axis machining at compound angles and 5 axis simultaneous machining

Turning

2 and 4 axis turning allowing you to program CNC lathe machines including automatic roughing, finishing, grooving, threading, cutoff and single point cycles

Wire EDM

A more intuitive, automatic and efficient method of generating EDM toolpaths and machine code. Developed specifically for programming 2 through 4-axis Wire EDM CNC Machines, unlike most CAM systems that use modified milling commands for EDM programming modules

Nestingworks

Advanced for design, prototyping and manufacturing nested parts in SOLIDWORKS. Optimise sheet metal and flat stock designs and support the transition from design to manufacturing for sheet metal and flat goods

Virtual Machine

Reduce shop floor setup time by eliminating dry runs for program validations and verify G-Code with one click! The first CAM software to integrate true G-code machine simulation directly within the CNC programming environment

CAMWorks Volumill

Improve machining time with this optional ultra high performance toolpath engine inside CAMWorks for 2.5 and 3 axis roughing operations. Ideal for complex 3D shapes and prismatic parts as well as both hard and soft materials that are hard to chip

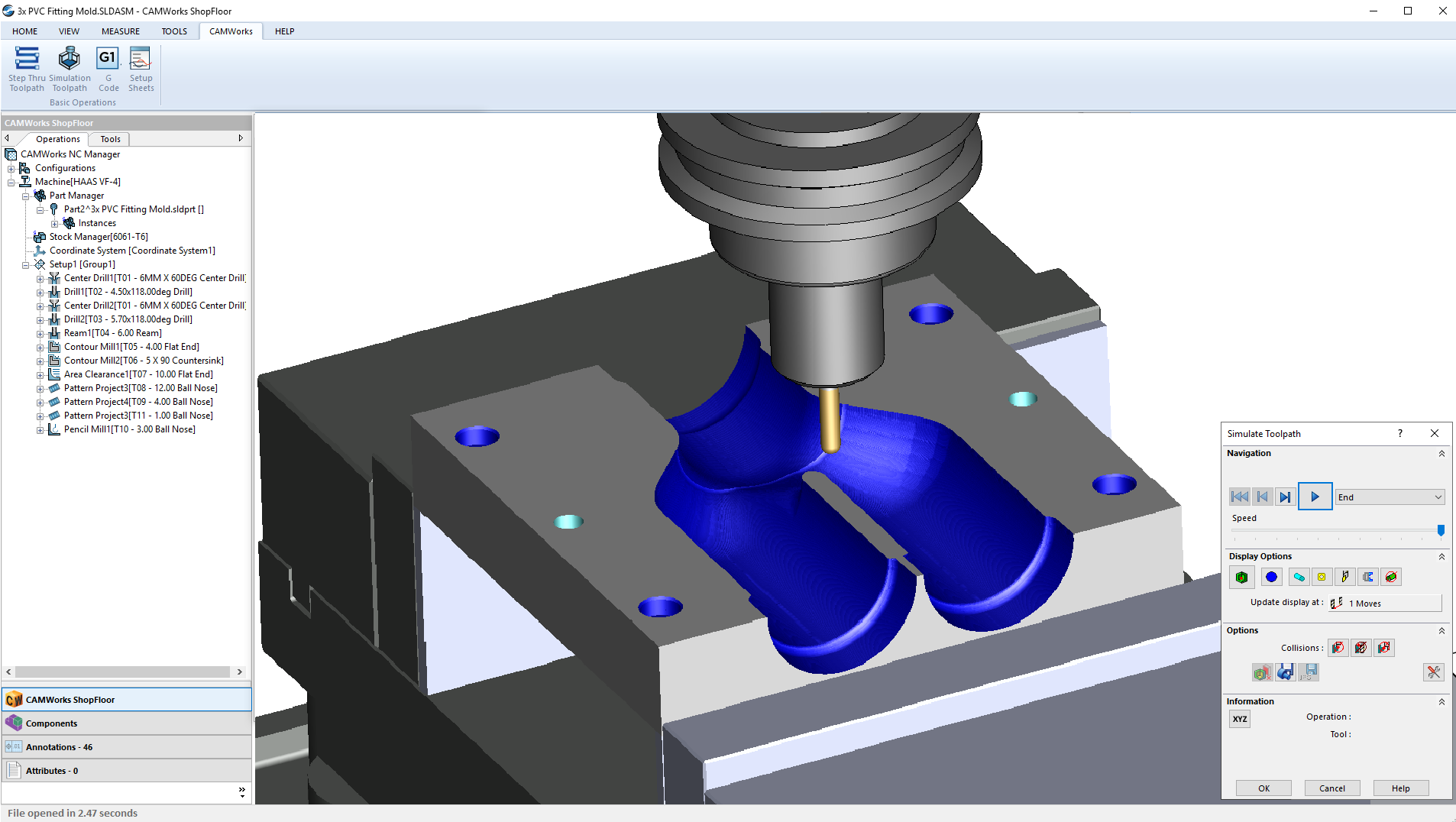

CAMWorks Shopfloor

Designed for CNC Machinists on the shop floor, CAMWorks Shopfloor. By providing 3D models with MBD & PMI data and CNC programming information to the shop floor in a single, compact digital format, it reduces errors and improves communication between CNC Programmers and Shopfloor Machinists

CAMWORKS Additive Manufacturing

The only completely integrated additive and subtractive manufacturing solution available for SOLIDWORKS. Thanks to data associativity, changes to manufacturing data update design changes automatically